Vessel Fuel Management

Vessel Fuel Management System

In addition to the immediate advantage of being able to operate a vessel more efficiently while underway, the installation of a Krill VFMS greatly enhances the competitiveness of the vessel in many important business areas.

- Value to Vessel Leasing Customers

Precise information needed to verify performance of the vessel at all times, in all modes of operation such as DP Mode, Transit or Idle.

- Fulfillment of Fuel System mandates

Meet leasing requirements of Exxon, Pemex and others. This delivers a distinct competitive advantage when negotiating leasing and charter contracts to operate vessels in areas wherever such mandates exist.

- Asset protection

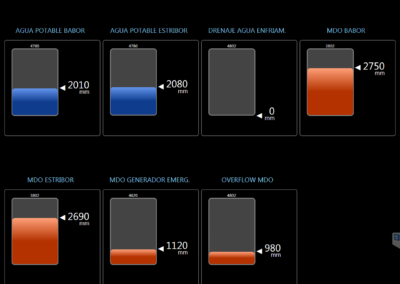

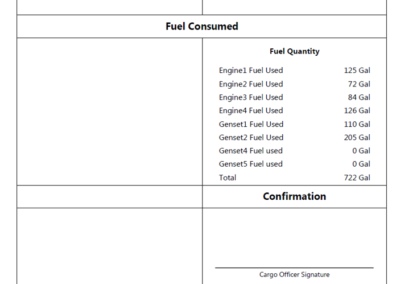

Accurate, real time, accounting of fuel loading, usage and offloading quickly identifies unusual fuel ‘usage’ patterns, often the result of fuel theft. Quick recognition of these events can be used to initiate swift action to remedy the situation, and results in a deterrence against future attempts.

- Emissions Control compliance

Full time emissions data-capture and stored history of real time emissions from the vessel provides verification that emissions regulatory requirements are being met, in addition to providing evidence of past compliance, if needed as evidence at a later date.

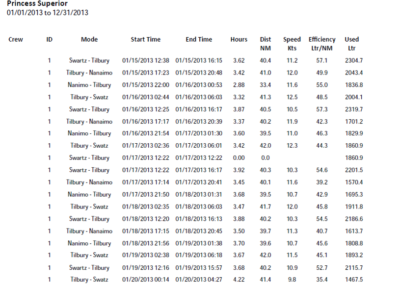

Voyage Management

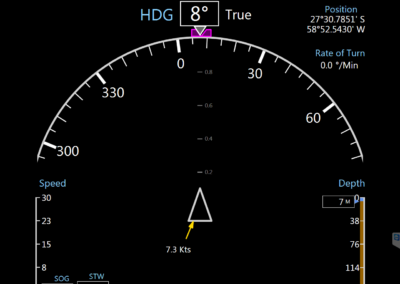

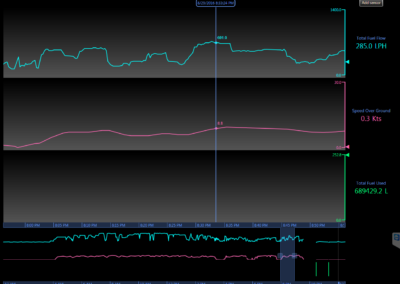

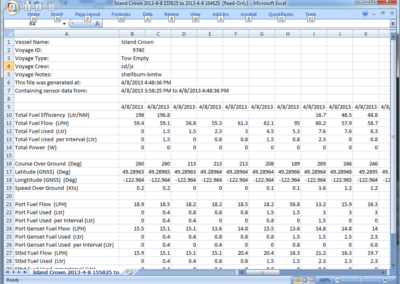

All of the information required to manage a particular voyage is presented on this page. Real time summary of total power, total instantaneous fuel rate, and vessel speed data is used to calculate fuel efficiency based on the amount of fuel is required to move the vessel one nautical mile. The vessel crew can use these data in order to meet their fuel usage targets.

A voyage can be started and stopped by manually by clicking a button, or automatically when an external relay contact (typically indicating active Dynamic Positioning) is closed, or when a certain geographical area is entered and left. All three voyage types are independent of each other, and can be running simultaneously at the same time.

Upon completing a voyage, a record of the total fuel usage, start and stop times, and the type of voyage is made and a new row will show in the Voyage Log below. If email reports are enabled, a copy of the voyage data can be emailed to any receipient with an Internet connection.

Automatic DP Mode

Voyage recording can be started and stopped automatically when an external event takes place such as when Dynamic Positioning is turned on or off. This allows fuel consumption to be recorded without manual intervention, eliminating inaccurate or missing voyages.

Geo Fencing

Voyage recording can also be started when a predefined geographical area is entered. Each area can be set to record an unlimited number of customized voyage type such as an environmental or a work zone, or a port of call where the vessel may enter an Idle state.

Real Time Data

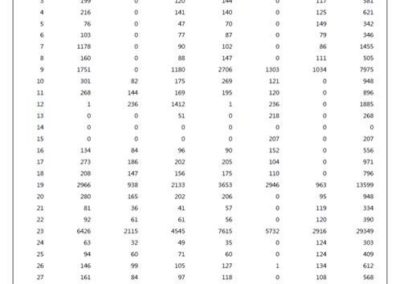

Basic engine RPM, fuel flow and accumulated fuel usage data is continuously collected from fuel sensors, as well as GPS data to track how fast the vessel is moving and the fuel burned. Any other type of sensor can be easily customized and displayed in a simple and intuitive manner.

Reporting

All collected sensor data can be used to easily generate sensor data reports in either print or Excel compatible spreadsheet format.

Free Remote Fleet Monitoring & Analysis

Vessel Operations Center (VOC) is a free software application that allows an unlimited number of remote locations to simultaneously monitor all of the vessels in their fleet in real time. Data from all vessels, including fuel consumption, navigation information, geo-fencing boundaries, automatic or manual vessel entry and exit activation, DP mode (automatic or manual activation), bunkering and other voyage events are synchronized with a central cloud based database server.

Reports such as fuel consumption by vessel and any time period can be locally created and exported to Excel for further analysis. Bunker activity is included in the information being delivered, along with fuel quality analysis. Personnel in accounting, operations and management can all have access to all of the vessel data such as fuel usage, position and voyage statistics instantly and simultaneously.

For the first time, the corporate office can instantly receive vital information as soon as a voyage is completed. Waiting for error-prone manually generated reports is now a thing of the past. Obtaining reports on each vessel is just a single click away.

How it Works

VOC works in conjunction with the VFMS vessel software which collects sensor data such as fuel flow, GPS position, speed and engine data every 15 seconds to a local SQL database located in the vessel’s Krill computer.

With an Internet connection, VFMS can also synchronize its local database with a central cloud based database server. The cloud server is also receiving database synchronizations from other vessels simultaneously, effectively merging all of the vessel databases into a single large database of unlimited size. The free VOC application simply reads the cloud server to display any data from any vessel of interest.

Own Your Data

No Access Fees

Our competitors typically upload your critical vessel data to their private, proprietary servers with questionable security, performance and financial reliability, and require you to pay to access your own data.

Krill uploads vessel data into robust, enterprise-grade, Microsoft Azure’s cloud database servers. These servers are administered by you for very little cost, providing end to end control over the entire data flow from the vessel to your desk.

Private and Secure

All data in transit and in storage is heavily encrypted, with an additional firewall at Microsoft Azure’s datacenter that allows only trusted Krill vessel data to be uploaded or accessed.

Microsoft Azure’s cloud database service is widely used by large corporations and government agencies for enterprise computing and storage. Azure offers the most comprehensive set of certifications. For more information on Microsoft Azure’s security, please click here.

ABS Certification

All of our flow sensors, computer hardware and displays are ABS certified for highest level of reliability and safety.